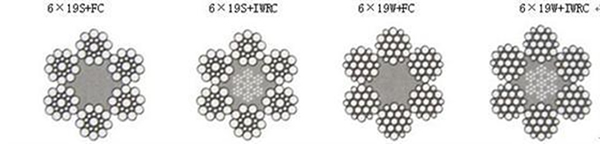

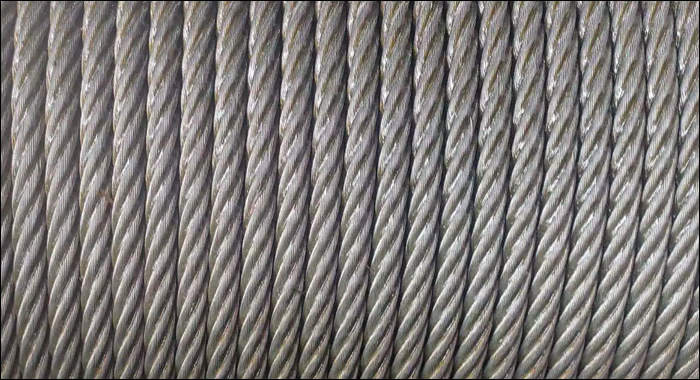

Everbright offers galvanized steel wire rope for general applications suitable for machinery, architecture, ship, fishery, forestry, mine, elevator and special uses, etc. The steel wire rope can be multi-strand with various tensile strength. The zinc coating all meets Chinese or international standards.

We also offer ungalvanized steel wire rope and flexible stainless steel wire ropes.

Wire Diameter:6-30mm

Nominal tensile stength:1570,1670,1770,1870,1960MPa

Galvanized Wire Ropes, Nonrotating Construction, Compacted, with sockets

Galvanized steel wire rope Ф24mm 35x7 IWRC

Construction: Ф24mm 35*7 IWRC, Nonrotating contruction, compacted, R.H.L.L;

Minimum breaking load: ≥552 kN;

Tensile Strength: ≥2160N/mm²

Galvanized steel wire rope Ф26mm 35x7 IWRC

Construction: Ф26mm 35*7 IWRC, Nonrotating contruction, compacted, R.H.L.L;

Minimum breaking load: ≥642 kN;

Tensile Strength: ≥2160N/mm²

Galvanized steel wire rope Ф42мм 8*26 + IWRC

Construction: Ф42mm 8x26 + I.W.R.C compacted R.H.R.L;

Minimum breaking load: ≥1660 kN;

Tensile Strength: ≥1960N/mm²

Open wedge socket

Open wedge socket for wire rope 23-26 mm

Minimum breaking load: ≥75MT

Included: pin, split pin, wedge and wire rope clips

Open spelter socket for wire rope 40-42 mm

Minimum breaking load: ≥170MT

Included: pin, split pin

Closed spelter socket

Closed spelter socket for wire rope 40-42 mm

Minimum breaking load: ≥170MT

Towing Wire Rope

Material: Galvanized Wire Rope φ72 mmX22M (ZAB 6x37+IWRC1960WITH THIMBLED EYES ON BOTH ENDS) SWL:210t MBL:350t

Specifications of each wire rope: Galvanized wire rope, and the diameter of the wire rope is φ72mmX22M (ZAB 6x37WS+IWRC1960WITH THIMBLED EYES ON BOTH ENDS). Both ends are pressed into marquise rings with steel sleeves. The inner diameter of the inner hole of the marquise-shaped annular steel sleeve is 192mm wide in the transverse direction and 230mm in the longitudinal inner diameter. The overall thickness of the marquise ring aluminum sleeve is 110mm on the side(for shackle use with an opening of 110mm), and the total length of the pipa head rope is 595mm. The overall marquise shape does not require opening, and the specifications and dimensions are used in conjunction with the shackles of other orders.

Technical parameters: safe load SWL: 210 tons T, breaking force MBL: 350 tons; tensile grade: 2160N/mm2

Certificate requirements: Product qualification certificate (coc certificate), ABS classification society certificate

Main Towing Wire Rope

Material: Galvanized Wire Rope φ72 mmX22M (ZAB 6x37+IWRC1960WITH THIMBLED EYES ON BOTH ENDS)

SWL:210t MBL:350t

Specifications of each wire rope: Galvanized wire rope, the diameter of the wire rope is φ72mmX22M (ZAB 6x37WS+IWRC1960WITH THIMBLED EYES ON BOTH ENDS). Both ends are pressed into marquise rings with steel sleeves. The inner diameter of the inner hole of the marquise-shaped annular steel sleeve is 192mm wide in the transverse direction and 230mm in the longitudinal inner diameter. The overall thickness of the marquise ring aluminum sleeve is 110mm on the side(for shackle use with an opening of 110mm), and the total length of the pipa head rope is 595mm. The overall marquise shape does not require opening, and the specifications and dimensions are used in conjunction with the shackles of other orders.

Technical parameters: safe load SWL: 210 tons T, breaking force MBL: 350 tons; tensile grade: 2160N/mm2

Certificate requirements: Product qualification certificate (coc certificate), ABS classification society certificate

Bridge cable wire rope

Material: Galvanized Wire rope φ72 mmX16M (ZAB 6x37WS+IWRC1960WITH THIMBLED EYES ON BOTH ENDS) SWL:210t MBL:350t

Galvanized wire rope, the diameter of the wire rope is φ72mmX16M (ZAB 6x37WS+IWRC1960WITH THIMBLED EYES ON BOTH ENDS). Both ends are pressed into marquise rings with steel sleeves. The inner diameter of the inner hole of the marquise-shaped annular steel sleeve is 192mm wide in the transverse direction and 230mm in the longitudinal inner diameter. The overall thickness of the marquise ring aluminum sleeve is 110mm on the side(for shackle use with an opening of 110mm), and the total length of the pipa head rope is 595mm. The overall marquise shape does not require opening, and the specifications and dimensions are used in conjunction with the shackles of other orders.

Technical parameters: safe load SWL: 210 tons T, breaking force MBL: 350 tons; tensile grade: 2160N/mm2

Certificate requirements: Product qualification certificate (coc certificate), ABS classification society certificate

With: ABS CERTIFICATE

General Introduction of Galvanized Wire Ropes:

1, WIRE ROPE SURFACE AND TENSILE STRENGTH

| Surface |

Tensile Strength/mpa |

| bright surface&B class zinc coating |

---- |

1570 |

1670 |

1770 |

1870 |

1960 |

2160 |

| AB class zinc coating |

---- |

1570 |

1670 |

1770 |

1870 |

1960 |

|

| A class zinc coating |

1470 |

1570 |

1670 |

1770 |

1870 |

|

|

2, ZINC COATING MIN

size |

Min. zinc coating |

B |

AB |

A |

0.15=d<0.2

0.2=d<0.25

0.25=d<0.4

0.4=d<0.5

0.5=d<0.6

0.6=d<0.7 |

10

14

19

28

38

48 |

57

66

81 |

71

86

104 |

0.7=d<0.8

0.8=d<1.0

1.0=d<1.2

1.2=d<1.5

1.5=d<1.9 |

57

66

76

86

95 |

81

90

104

114

124 |

114

124

142

157

171 |

1.9=d<2.5

2.5=d<3.2

3.2=d<4.0

4.0=d<4.4 |

104

119

128

142 |

142

157

180

190 |

195

218

238

247 |

Galvanized Steel Wire Rope shall be made meeting GB/T 20118-2006 standard, details as listed below:

Standard Wire Rope Specifications:

| size/mm |

Weight (kg/100m) |

Tensile/Mpa |

| 1570 |

1670 |

1770 |

1870 |

| Mini Breaking Force/kN |

| NFC |

SFC |

IWR |

FC |

IWR |

FC |

IWR |

FC |

IWR |

FC |

IWR |

| 3 |

3.16 |

3.1 |

3.6 |

4.34 |

4.69 |

4.61 |

4.99 |

4.89 |

5.29 |

5.17 |

5.59 |

| 4 |

5.62 |

5.5 |

6.4 |

7.71 |

8.34 |

8.2 |

8.87 |

8.69 |

9.4 |

9.19 |

9.93 |

| 5 |

8.78 |

8.6 |

10 |

12 |

13 |

12.8 |

13.9 |

13.6 |

14.7 |

14.4 |

15.5 |

| 6 |

12.6 |

12.4 |

14.4 |

17.4 |

18.8 |

18.5 |

20 |

19.6 |

21.2 |

20.7 |

22.4 |

| 7 |

17.2 |

16.9 |

19.6 |

23.6 |

25.5 |

25.1 |

27.2 |

26.6 |

28.8 |

28.1 |

30.4 |

| 8 |

22.5 |

22 |

25.6 |

30.8 |

33.4 |

32.8 |

35.5 |

34.8 |

37.6 |

36.7 |

39.7 |

| 9 |

28.4 |

27.9 |

32.4 |

39 |

42.2 |

41.6 |

44.9 |

44 |

47.6 |

46.5 |

50.3 |

| 10 |

35.1 |

34.4 |

40 |

48.2 |

52.1 |

51.3 |

55.4 |

54.4 |

58.8 |

57.4 |

62.1 |

| 11 |

42.5 |

41.6 |

48.4 |

58.3 |

63.1 |

62 |

67.1 |

65.8 |

71.7 |

69.5 |

75.1 |

| 12 |

50.5 |

50 |

57.6 |

69.4 |

75.1 |

73.8 |

79.8 |

78.2 |

84.6 |

82.7 |

89.4 |

| 13 |

59.3 |

58.1 |

67.6 |

81.5 |

88.1 |

86.6 |

93.7 |

91.8 |

99.3 |

97 |

105 |

| 14 |

68.8 |

67.4 |

78.4 |

94.5 |

102 |

100 |

109 |

107 |

115 |

113 |

122 |

| 16 |

89.9 |

88.1 |

102 |

123 |

133 |

131 |

142 |

139 |

150 |

147 |

159 |

| 18 |

114 |

111 |

130 |

156 |

169 |

166 |

180 |

176 |

190 |

186 |

201 |

| 20 |

140 |

138 |

160 |

193 |

208 |

205 |

222 |

217 |

235 |

230 |

248 |

| 22 |

170 |

166 |

194 |

233 |

252 |

248 |

268 |

263 |

284 |

278 |

300 |

| 24 |

202 |

198 |

230 |

278 |

300 |

295 |

319 |

313 |

338 |

331 |

358 |

| 26 |

237 |

233 |

270 |

326 |

352 |

346 |

375 |

367 |

397 |

388 |

420 |

| 28 |

275 |

270 |

314 |

378 |

409 |

402 |

435 |

426 |

461 |

450 |

487 |

| 30 |

316 |

310 |

360 |

434 |

469 |

461 |

499 |

489 |

529 |

517 |

559 |

| 32 |

359 |

352 |

410 |

494 |

534 |

525 |

568 |

557 |

602 |

588 |

636 |

| 34 |

406 |

398 |

462 |

557 |

603 |

593 |

641 |

628 |

679 |

664 |

718 |

| 36 |

455 |

446 |

518 |

625 |

676 |

664 |

719 |

704 |

762 |

744 |

805 |

| 38 |

507 |

497 |

578 |

696 |

753 |

740 |

801 |

785 |

849 |

829 |

896 |

| 40 |

562 |

550 |

640 |

771 |

834 |

820 |

887 |

869 |

940 |

919 |

993 |

| 42 |

619 |

607 |

706 |

850 |

919 |

904 |

978 |

959 |

1040 |

1010 |

1100 |

| 44 |

680 |

666 |

774 |

933 |

1010 |

993 |

1070 |

1050 |

1140 |

1110 |

1200 |

| 46 |

743 |

728 |

846 |

1020 |

1100 |

1080 |

1170 |

1150 |

1240 |

1210 |

1310 |

Steel Wire Rope for Elevators:

| size |

weight |

tensile |

| 1570 |

1670 |

1770 |

1870 |

1960 |

| mm |

Kg/100m |

Mini Breaking Force/kN |

|

FC |

IWR |

FC |

IWR |

FC |

IWR |

FC |

IWR |

FC |

IWR |

FC |

IWR |

| 6 |

13.3 |

14.6 |

18.6 |

20.1 |

19.8 |

21.4 |

21.0 |

22.7 |

22.2 |

24.0 |

23.3 |

25.1 |

| 7 |

18.1 |

19.9 |

25.4 |

27.4 |

27.0 |

29.1 |

28.6 |

30.9 |

30.2 |

32.6 |

31.7 |

34.2 |

| 8 |

23.6 |

25.9 |

33.1 |

35.7 |

35.2 |

38.0 |

37.3 |

40.3 |

39.4 |

42.6 |

41.4 |

44.6 |

| 9 |

29.9 |

32.8 |

41.9 |

45.2 |

44.6 |

48.0 |

47.3 |

51.0 |

49.9 |

53.9 |

52.4 |

56.5 |

| 10 |

36.9 |

40.5 |

51.8 |

55.8 |

55.1 |

59.4 |

58.4 |

63.0 |

61.7 |

66.5 |

64.7 |

69.8 |

| 11 |

44.6 |

49.1 |

62.6 |

67.6 |

66.6 |

71.9 |

70.6 |

76.2 |

74.6 |

80.5 |

78.3 |

84.4 |

| 12 |

53.1 |

58.4 |

74.6 |

80.4 |

79.3 |

85.6 |

84.1 |

90.7 |

88.6 |

95.8 |

93.1 |

100 |

| 13 |

62.3 |

68.5 |

87.5 |

94.4 |

93.1 |

100 |

98.7 |

106 |

104 |

112 |

109 |

118 |

| 14 |

72.2 |

79.5 |

101 |

109 |

108 |

116 |

114 |

123 |

120 |

130 |

127 |

137 |

| 16 |

94.4 |

104 |

132 |

143 |

141 |

152 |

149 |

161 |

157 |

170 |

166 |

179 |

| 18 |

119 |

131 |

167 |

181 |

178 |

192 |

189 |

204 |

199 |

215 |

210 |

226 |

|